Simulating the program to verify toolpaths and detect any potential errors or collisions before executing the Procedure.

Website shows resale Market tickets Selling prices can be above or below confront benefit Not affiliated with any box office or location Research by celebration or venue

The mattress is simply a base plate that rests over the desk, supporting other machine parts. The carriage runs about the bed which happens to be heat-treated to withstand the machining effects.

The CNC machine commences functioning soon after acquiring Guidelines from a pc-aided design (CAD) file. The components of a CNC lathe machine, including the rotating spindle in which the workpiece is held plus the chopping tool, do the job in unison to provide an element matching the comprehensive technical specs outlined from the CAD file.

Last but not least, this lathe has the extra good thing about the Mazak SmoothC. This is a highly advanced control panel that delivers an improved consumer expertise and faster machining occasions.

. Slicing feed reveals the distance the slicing tool moves for every a single convert from the workpiece. The gap is measured axially.

The Visit this page piece or maybe the machine may be incorrectly positioned, triggering a crash where by the tools split. Incorrect code or other factors can add.

Control System: CNC lathes are controlled by a pc, While frequent lathes are manually operated.

Turning vs. Drilling: Drilling will involve making holes in the workpiece utilizing a rotating drill little bit, Whilst turning focuses on shaping the exterior surface area of your workpiece.

Precision and Accuracy: CNC lathes provide considerably higher precision and regularity compared to normal lathes.

The technological storage or accessibility that may be employed exclusively for statistical applications. The specialized storage or obtain that is definitely utilized completely for anonymous statistical functions.

Set up: Future, you set up the CNC lathe. This entails picking and putting in the suitable slicing tools and securing the workpiece on to the machine.

Continuous monitoring from the machining method to be certain accuracy and detect any deviations or issues which could arise.

Coming regular with the TL-1 is a 1GB software memory, which is an abundance of storage space for complex patterns and courses. The Haas drop attribute helps you to instantaneously insert program information by using a wireless connection, conserving you time and Electricity.

Michael Bower Then & Now!

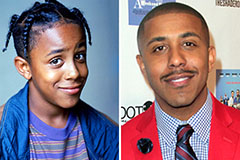

Michael Bower Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now! Daryl Hannah Then & Now!

Daryl Hannah Then & Now! Robin McGraw Then & Now!

Robin McGraw Then & Now!